63# Beijing Road,Huangdao District,Qingdao,China. PO:266555 +86-158 79678188 [email protected]

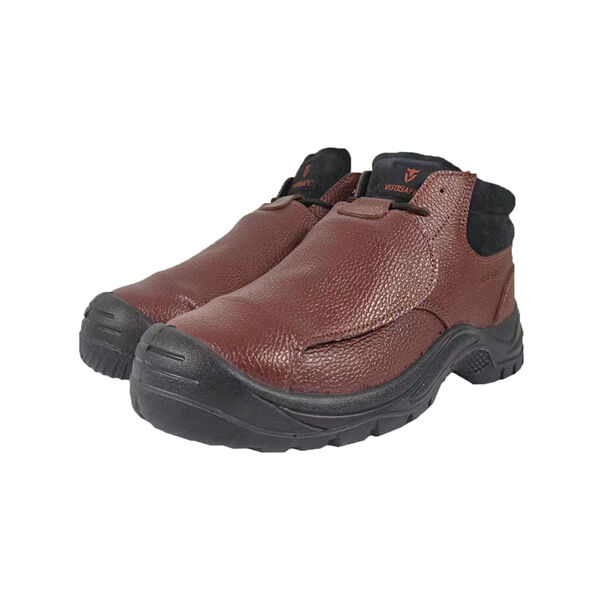

Welding safety boots, if you are in the welding line of work is among one of those protective elements that your feet will need to have when it comes into such an intense environment. VITOSAFE best working boots is manufactured from state-of-the-art materials and designs to provide unsurpassed protection, comfort welders of many industries find great benefit when they are wearing these specially designed specialized boots. Boots come in an enormous selection of dimensions as well as designs, so they deal with the particular demands of welders making them without a question necessary security devices.

Fact is, welder safety boots as a category continue to change and evolve faster given more technology advancements that make them better in creating protection for your feet. A few of the key new innovative choices on welding safety boots include.

Metatarsal Guards - VITOSAFE best safety toe boots protects the bones of your toes, tendons and tissues from hard impacts with Metatarsals guards preventing compression injuries to these areas.

Lightweight materials: Welding safety boots are made from lightweight materials, including composite and aluminum; this way of construction is designed for welding will reduce fatigue and improve maneuverability.

Electric Hazards: Most welding safety boots ate siblings with an electric hazards feature, protecting the worker from electrical shorts and other sorts of brothers that are present in most welding environments.

Slip Resistant Soles - Boots with slip resistant soles will have better grip to prevent slipping on wet surfaces

One of the most annoying things is when you're out welding in the elements and your feet are getting wet from all that water-logged ground; misery loves company.

Safety boots are more advanced and include many new features that make welding work safer, such as metatarsal guards (among others), lighter weight materials or even elements for electrical hazard protection, slip-resistant soles and water resistance.

Adjusting To Use The Welding Safety Boots

Using welding safety boots is easy and it involves the steps;

Good Fitting: Always select the welding protective shoes that fit perfectly in toe area, so that your fingers can move freely.

Put on the boots: Slide your feet into the boots to ensure a snug fit - if necessary tighten up laces or any buckles, etc.

Check: Conduct regular boot checks, replacing any worn or damaged boots as necessary to maintain full protection.

Proper Maintenance - Keeping your welding steel toe boots free from the dirt and debris that dulls them down making sure they will not protect you any longer.

Store: The trick is to store your welding safety boots in a place that will keep them for yanks of ages.

Therefore, if you conform to either one of the steps without fail then your welding safety boots are all set for a maximum performance and even life span so get them up today as it will increase some protection features that protects yourself in the workspace.

Stepping Up Both Your Welding Safety Boot Game and Receiving Goods With The Promise of Quality and Service

While selecting welder safety boots in order to give a high-end protection and longevity, quality of style become quintessential for service.

Quality Assurance - Always go for the industry’s leading manufacturers of welding boots, quality in work wear.

The supplier or vendor must also provide an excellent customer service, able to guide your company in the best products (or storage conditions), delivering when you most need and if necessary solve any setbacks that may arise after purchase.

Given how important a role such protective footwear plays choosing welding safety boots is a question of getting excellent quality and service back up as well.

Welding safety boots are considered a mandatory piece of protective gear for any welder, so it is important to know what benefits they provide. Benefits of Welding safety Boot

Powerful protection :Take care! Wearing the correct boots will give you benefit to protect your feet while working in hazardous welding environments. Welding safety boots are made using materials with comfort padding that gives cushion and outsole to set in your feet all day long secure from heat, and creates the product so tough it will never disappoint you.- Protection: These welding leather shoes come built with steel toe caps underfoot puncture resistance plates (anti-puncture) as well slip-resistant anti-static sole protect protection. With breathable linings, padded collars and cushioned insoles the entire work day through even during long welding hours.- Welding Safety Boots are most durable. They are constructed from durable material like leather, rubber and heat-resistant synthetics able to endure the tough demands of welding work. They are stitched with high quality threading too tough and durable to fall apart fast.- Occupational Health And Safety Compliance: Welding safety boots comply occupational health guidelines prepared by an array of institutions. These rules make sure that welders use proper personal protective equipment, like work boots for safety to lessen and mitigate preventable injuries. Welding safety boots come with a lot of benefits. They keep your feet safe, they are comfortable for you to wear all day long, and last a considerable length.

Welding footwear is engineered using advanced technology and materials to comply with the new requirements of welders. Here are some examples of innovative features made welded into welding safety boots:- Metatarsal guards: These have been used in the upper part of the shoe to shield Mar-row and tender tissues from damage. Safety Features of Welding Safety Boots Following are the safety features that make welding boots safe :Impact-resistant toes: The need for impact- resistant toe boxes in a welding boot cannot be emphasized enough as they protect welders from falling objects or heavy machinery Electrical hazard protection Water-resistance Slip-resistant soles Compression resistance (sole) -These feature imitate anti-penetration what it does is deflect impacts to give an enhanced level on compression injuries Lightweight materials. Welding safety boots have been created with new materials that allow them to be stronger. These are; anti-injury iron, lightweight material for putting on and off more easily, electric shock protection (if needed), non-slip soles/hard sole | instep high to keep dry. Undefined

It Is Easy To Use Welding Safety Boots How to use welding safety boots:-Here are the steps for using Welding Safety Boots:1.

1: Begin with the correct size. The first thing you should do is choose your welding safety boots in a different way. The shoes must be snug, giving space for the toes to move freely.

2. Step 3: Pop the boots on Slip your feet in and ensure that there's a little room at your toe end. Tie the laces well or close any fasteners that will help you keep them fit.

3. Look out for irregularities: Make sure you check the boots every now and then to see if they show signs of distress. Make sure you replace any damaged boots for the utmost safety.

4. Clean boots: Keep welding safety shoes clean from dirt, debris which can cause damage on your equipment. 5. Proper storing your boots away from high temperatures and also direct sunlight. Wearing Welding Safety Boots Isn't Difficult. Simply ensure they fit, wear them check for damage clean and store in a safe place.

Safety Shoes mainly sold Italy-U-power, UK-Black rock beta, South America-welding safety boots, South Africa-DOT. VITOSAFE provides services over 20.000 customers more than 60 countries.

have more than 8 excellent designers, has improved ability new welding safety boots development. develop about 5 new upper designs per month, one two outsole designs per year, help our customers win in the market.

This where can benefit from single-stop shopping. have a welding safety boots team serve you. Our sales staff will keep track each step before, during and after production ensure that customers are aware of the actual progress their order.

VITOSAFE creates 100000 pairs shoes every month. also produce 2 normal welding safety boots injections Desma injective, 1 cement product line. Outsole technology: PU/PU, PU/TPU, PU/RUBBER, Eva/Rubber, Rubber...